Project Categories

Federal Projects

Joint Base Andrews, Maryland

Jordan Environmental Services staff provides engineering, planning, and cost estimating for environmental restoration, environmental compliance, pollution prevention, conservation planning, and management and operations support for the Joint Base Andrews (JBA) Environmental Restoration Program (ERP). Managed all environmental remediation activities and developed all Remedial Investigations (RIs), Feasibility Studies (FSs), Proposed Plans (PPs), Records of Decision (RODs), Remedial Designs (RDs), Remedial Action – Constructions (RA-Cs), Remedial Actions – Operations (RA-Os), Response Completes (RCs), Long Term Monitoring (LTM) efforts, and Quality Assurance Project Plans (UFP-QAPPs). Management of JBA ERP sites included but is not limited to ire Training Areas; Hazardous Waste Landfills; Petroleum, Oil, and Lubricant (POL) yards; massive chlorinated solvent plumes; very large jet fuel LUSTs; former dry cleaning facilities; and Solid Waste Management Units.

Joint Base Andrews - Mold Abatement

Jordan Environmental Services (JES) conducted several mold abatement projects on Joint Base Andrews, Maryland (JBA). The projects were completed on schedule and JES personnel were commended for having all licenses, registrations, insurance, and credential paperwork readily available for the Health and Safety Managers. Air Force personnel were very satisfied with the work performed by our crews and thanked us for our service.

Joint Base Andrews Diesel Spill Cleanup

Jordan Environmental Services personnel performed the environmental remediation services at the Dental Clinic Diesel Spill Site at Joint Base Andrews. All contaminated soils were excavated, removed, and disposed of at an appropriate landfill facility. The soils were tested and the Maryland Department of the Environment (MDE) closed the case number.

Batelands-Mobil-Oil-Site

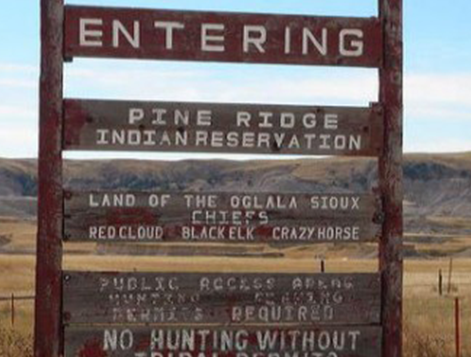

Batesland (former Mobil Oil) Site, Pine Ridge Indian Reservation, Batesland, South

Dakota

Worked as a Subcontractor to the Prime Contractor. Upgraded the

existing AS/SVE system at the Batesland site. Activities included engineering, siting, and

construction of additional AS and SVE wells to optimize and increase the efficiency of the

system. System optimization resulted in a 50% increase in mass removal. The AS and SVE wells

were then connected to the centralized manifold. The system start-up was successful and

Jordan Environmental analyzed the system performance, assessed removal rates of the system,

and determined baseline hydrocarbon concentrations for use in the upcoming hydrocarbon

recovery project. Reports generated included the Quality Assurance Project Plan (UFP-QAPP),

AS/SVE System Installation Report, and a Baseline Environmental Assessment.

Old-Hill-Top-Gas-Station-Utah

Old Hill Top Gas Station LUST Site, Uintah and Ouray Reservation, Vernal, Utah Jordan Environmental Services worked as the Subcontractor to the Prime Contractor to conduct two rounds of in situ chemical oxidation (ISCO) at the Old Hill Top Gas Station as directed by EPA Region 8. The injections were very successful at reducing benzene, toluene, ethylbenzene, xylene (BTEX), and other petroleum hydrocarbons. Reports generated included Injection Reports, O&M Reports, and a Remedial Action Completion Report.

EPA - Pine Ridge Oil Pine Ridge Indian Reservation

Pine Ridge Oil (PRO) LUST Site, Pine Ridge Indian Reservation, Pine Ridge, South Dakota Worked as a Subcontractor with the Prime Contractor. Activities included the injection of a surfactant/ISCO into the source area at the PRO LUST site. A total of 1,600 gallons of reagent were injected over two injection events. Subsequent groundwater measurements indicate that the injections were successful in liberating sorbed hydrocarbon products. This product was then recovered via a high vacuum extraction (HVE) event and a pneumatic pumping event. A total of approximately 230 gallons of free product were successfully removed from the aquifer. Reports generated included Operation and Maintenance (O&M) reports, a Surfactant Injection Report, and an Enhanced Fluid Recovery Report.

Cheyenne-Indian-Res-Montana

Custer’s Last Camp (CLC) LUST Site, Northern Cheyenne Indian Reservation, Busby, Montana Worked as a Subcontractor with the Prime Contractor. Activities included the design, installation, and operation of an SVE system that dramatically reduced petroleum hydrocarbons in groundwater at CLC during its time of operation (1.5 years to date). System operations resulted in 70% mass removal. Bioaugmentation efforts at the site included several rounds of injections of emulsified oil substrates (EOS) to address chlorinated solvents including 1,2-dichloroethane (1,2-DCA). Reports generated included the UFP-QAPP, O&M reports, and Remedial Action - Operations reports.

Lead-Based Paint and Asbestos Abatement Gov Facility

Jordan Environmental Services staff provides engineering, planning, and cost estimating for environmental restoration, environmental compliance, pollution prevention, conservation planning, and management and operations support for the Joint Base Andrews (JBA) Environmental Restoration Program (ERP). Managed all environmental remediation activities and developed all Remedial Investigations (RIs), Feasibility Studies (FSs), Proposed Plans (PPs), Records of Decision (RODs), Remedial Designs (RDs), Remedial Action – Constructions (RA-Cs), Remedial Actions – Operations (RA-Os), Response Completes (RCs), Long Term Monitoring (LTM) efforts, and Quality Assurance Project Plans (UFP-QAPPs). Management of JBA ERP sites included but is not limited to ire Training Areas; Hazardous Waste Landfills; Petroleum, Oil, and Lubricant (POL) yards; massive chlorinated solvent plumes; very large jet fuel LUSTs; former dry cleaning facilities; and Solid Waste Management Units.

National Park Service, Asbestos and Mold Abatement Projects

Jordan Environmental Services (JES) conducted several asbestos and mold abatement projects for the Department of the Interior/National Park Service (DOI/NPS). Upon being awarded the projects, JES conducted the Site Reconnaissance the following day, completed the projects within two business days, and issued the Clearance Letters to the NPS on the fourth day. The NPS was astounded by our level of service and how quickly the projects were completed.

Fort-Hunt-Nat-Park-Lead-Based-Paint-Inspection

Jordan Environmental Services staff provides engineering, planning, and cost estimating for environmental restoration, environmental compliance, pollution prevention, conservation planning, and management and operations support for the Joint Base Andrews (JBA) Environmental Restoration Program (ERP). Managed all environmental remediation activities and developed all Remedial Investigations (RIs), Feasibility Studies (FSs), Proposed Plans (PPs), Records of Decision (RODs), Remedial Designs (RDs), Remedial Action – Constructions (RA-Cs), Remedial Actions – Operations (RA-Os), Response Completes (RCs), Long Term Monitoring (LTM) efforts, and Quality Assurance Project Plans (UFP-QAPPs). Management of JBA ERP sites included but is not limited to ire Training Areas; Hazardous Waste Landfills; Petroleum, Oil, and Lubricant (POL) yards; massive chlorinated solvent plumes; very large jet fuel LUSTs; former dry cleaning facilities; and Solid Waste Management Units.

Large-Scale Federal Government Projects (Asbestos/Lead-Based Paint/Mold)

Jordan Environmental Services has conducted large-scale lead-based paint, asbestos, and mold remediation projects for numerous government clients including but not limited to the CIA, the FBI, the DGS, the DOI, the NPS, and numerous DOD facilities. Many projects are still ongoing and all of our clients have been extremely satisfied with our prices, professionalism, and customer service.